It is said that the J-20 fighter is the most powerful fifth-generation fighter currently. It attracted much attention upon its launch. First of all, the operating costs of the J-20 will be significantly reduced, because the WS-15 has higher reliability and maintainability, and the engine life will be much longer than that of the WS-10C, which will help reduce the entire life cycle cost of the fighter jet. And this means that China has developed a long-life turbofan engine. This is equivalent to China achieving a major breakthrough in the fields of technology and materials. Secondly, the J-20 can significantly improve endurance. The thrust-to-weight ratio of the WS-15 is expected to be comparable to that of the F-135, and the J-20 is expected to achieve supersonic endurance at a higher speed.

YouTuber The RC Geek is building a cool turbofan engine model kits project.

We are taking a look at something different today now. I love ST static models and plastic models because I grew up building plastic models. And that's really where I honed a lot of the skills that I use on the RC models. But today we're taking a look at this small turbofan engine kit that comes from Stirlingkit, the world’s smallest jet engine model in assembly version, inspired by a famous China J-20 fighter.

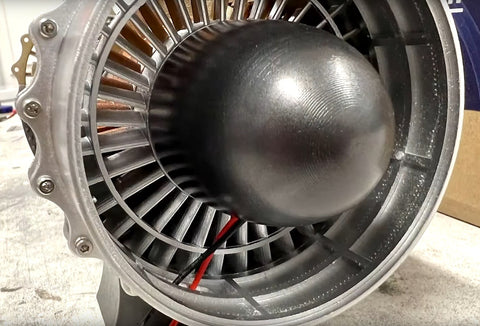

It is an all 3D printed ws-15 turbofan engine with a nice cutaway that is motorized. so you can see all of the working internals of the jet engine.

and it's pretty awesome because it is motorized. All you need to do is to find the the stand, a place where you can put two AAA batteries and then there's a plug where you can plug it together and all of the rotating machinery in there rotates with the battery now. I did find there was a bit of drag, you do need a pretty high-power set of AAA's so I ended up just plugging in a 2s lipo into it and that helped. it moves through any kind of difficulties from friction or anything like that and it spun with the 2s lipo it spins super nicely so you get are ally good idea of how it all works you know from a stem perspective this is a fantastic project to help learn and explore how turban engines and how turbofan engines work now from an assembly standpoint.

it took me about 1 and 1 half to 2 hours to put together. there are several pieces in there now they are all 3D printed except some shafts and some bearings that are included uh but otherwise you know everything fits together pretty nicely it all comes pre-painted you just bolt it together and so you do have to take your time to get it there.

Now the instructions themselves aren't particularly descriptive. They do give you the pictures that you need for each assembly step but what's difficult to discern is the orientation of the blades as you are putting the thing together because everything should be oriented a certain way within the engine itself. so your hand trying to discern that up front wasn't the easiest cuz it wasn't obvious in the instructions themselves. so you know I've got the picture on the video, you can see the orientation of everything and how it works. and so as they are rotating, you can see all the rotating machinery versus what's stationary. and so yeah it's it's really great representation to see how these turban engines work now.

in the process of assembling the model, I was kind of lamented. I like man all these 3D-printed Parts. how come they didn't give a 3D printed tool for tightening the nuts well? I found out near the end there was one included. it indeed helped with all of the final assembly. imagine that there are a number of screws and nuts, that you do have to tighten down and so that's where a lot of that time comes in, and so having that tool helps the process go a bit quicker.

so once it's fully assembled, it's a nice-looking representation. it's something you can set on, you know, your desk at work or in your office or your shop or what have you, but also from a STEM perspective, it is a fantastic project to show the inner workings of a turbofan engine because you know, a turban engine in its purest form is fairly simple but a lot is going on especially when in today's, you know, the modern technology of turban engines being able to see how it all works is fantastic.

All right so here is the completed engine and so I wanted to talk through just how these engines work. you can see all of the rotating components in here and so this is what is called a turbofan and it's a low bypass turbofan and so what that means is these three elements here.

this is a multi-stage fan. so when that spins you have air that is being fed into the core turbine which starts here.

and this is the compressor which we'll talk about in a minute. but you also have air that bypasses around the whole core turbines as well and so you are getting a combination of thrust from the fan as well as from the core turbine itself hand so when you talk about this being a low bypass that means there's not a whole lot of air being bypassed around the turbine.

when you talk about a high bypass turbine, you're going to have a much larger fan and a much larger channel for bypass air and so when this spins you've got the fan feeding air into now the core turbine.

and that is this section here and so you have this multi-stage compressor here. this is 1 2 3 4 five a six-stage compressor.

In total, the engine job is similarly detailed, complete with plastic materials, and paint work is needed. The result looks as close to the J-20 fighter WS-15 engine even though it's a model only. While perhaps not as exciting as a genuine WS-15 turbofan engine restoration, these model videos are immensely satisfying to watch.

0 comments